Cone crusher basics in 4 minutes - SRP

Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive.

More

Analysis and optimization of cone crusher performance

2009年10月1日 The key performance parameters of a cone crusher include the output; particle size and particle shape. In previous research on cone crusher performance the

More

A Detailed Overview of Cone Crushers and What You

2020年6月3日 Usually, these crushers deliver a 4:1, 5:1, or 6:1 reduction ratio. As you reduce the closed side setting to produce smaller material, you also reduce the capacity

More

Cone Crushers (Parts of a Cone Crusher) Explained - saVRee

The main components of a cone crusher include the main shaft, mantle, concaves, cone, eccentric bushing, drive, crown gear, frame, and tramp release mechanism

More

A review of modeling and control strategies for cone

2021年8月15日 We review the state of the art developments in process modeling and cone crusher control from 1972 to 2020. • The steady-state model of Whiten (1972) is still used

More

Understanding the Cone Crusher Working Principle: How

2023年2月23日 In summary, the hydraulic system is a crucial component of the cone crusher that enables precise control over the machine’s various functions. It allows for

More

Cone Crusher Working Principle Animation

2012年8月15日 Cone crusher has a less steep crushing chamber and more parallel zone between crushing zones. Cone crusher parts. It breaks the rocks by squeezing it between the gyrating spindles. These spindles

More

Chamber Optimization for Comprehensive Improvement

2021年3月15日 Figure 1. (a) Structure diagram and (b) functional principle diagram of cone crusher. The crushing of ore is directly related to the compression ratio, and the bottom

More

(PDF) Cone Crusher Performance - ResearchGate

2015年5月13日 In this thesis a method for prediction of cone crusher performance is presented. The model is based on the laws of mechanics and constitutive relations concerning rock breakage characteristics.

More

Cone crusher basics in 4 minutes - SRP

Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing ...

More

Extension, Validation, and Simulation of a Cone Crusher

2019年1月1日 This work presents an extension and validation for a control oriented model of cone crushers. Compared to earlier work, the aspect of energy consumption was added to the model. Validation was carried out using measurement data from two different crusher models and was based both on laboratory data and field experiment data. Using the

More

Dynamic modeling and simulation of cone crushing circuits

2013年4月1日 The cone crusher CSS is controlled by means of a hydraulic piston. The actual process model depends on the hydraulic system configuration. ... It is also possible to calculate the material level h in the feed hopper, which is a nonlinear function of V and depends on crusher and feed-hopper geometry (Sbarbaro, 2005). The material flow in the ...

More

Chamber Optimization for Comprehensive Improvement

2021年3月15日 This study aims to analyze the impact of key structural parameters such as the bottom angle of the mantle, the length of the parallel zone, and the eccentric angle on the productivity and product quality of the cone crusher and optimize the crushing chamber to improve the crusher performance. The amount of ore in the blockage layer was

More

Geometric analysis of cone crusher liner shape

2021年1月1日 This simplicity also allowed the Whiten crusher model (Whiten, 1972) to describe jaw crusher performance with only three parameters – K1 which correlates with CSS, K2 which relates to OSS and t 10 which provides for a similar degree of severity of breakage for each particle which is caught and a probability curve for capture.The

More

Cone Crusher Working Principle Animation

2012年8月15日 Cone crusher has a less steep crushing chamber and more parallel zone between crushing zones. It breaks the rocks by squeezing it between the gyrating spindles. These spindles are fully

More

Applied Sciences Free Full-Text Prediction of

2016年12月3日 Cone crushers are used in the aggregates and mining industries to crush rock material. The pressure on cone crusher liners is the key factor that influences the hydraulic pressure, power draw and liner

More

A Comprehensive Guide to Secondary Crusher Types

2023年2月28日 Learn about the different types of secondary crushers, including impact crushers, cone crushers, roll crushers, and jaw crushers, and their functions, advantages, disadvantages, applications, and factors to consider when selecting them. Discover case studies and examples of successful applications, as well as future developments in

More

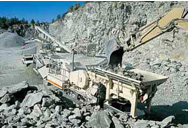

Reliability centered maintenance of cone crusher: a case

2014年2月25日 A cone crusher is used for crushing rock. The vast majority of these installations are found in mineral processing plants. The Reliability of the crusher influences the productivity of the plant. The purpose of this paper is to focus the application of reliability centered maintenance with an aim to improve the reliability of the cone crusher. reliability

More

Understanding Cone Crusher Parts Names, Functions, and

2023年2月22日 Description: This article provides a comprehensive guide to understanding the different parts of cone crushers, their functions, and the importance of proper maintenance. It covers various types of cone crusher parts, common issues and solutions, and future developments in the industry. Whether you are in the market for a new cone

More

Study on the technical parameters model of the

A cone crusher is a machine that crushes rock materials with high efficiency and low power consumption; it is one of the typical road construction equipment. To improve the production efficiency, mechanical

More

How it Works: Crushers, Grinding Mills and

2017年6月2日 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the

More

Cone Crusher Working Principle Animation

2012年8月15日 Cone crusher has a less steep crushing chamber and more parallel zone between crushing zones. It breaks the rocks by squeezing it between the gyrating spindles. These spindles are fully

More

(PDF) COMPARISON OF SECONDARY CRUSHING

2020年9月20日 Schematic illustration of the crushers considered in this study a) Cone crusher b) Horizontal shaft impact (HSI) crusher (Dr: rotor diameter, Mo: mainframe opening of the crusher chamber, CSS ...

More

Understanding Cone Crusher Parts Names, Functions, and

2023年2月22日 Description: This article provides a comprehensive guide to understanding the different parts of cone crushers, their functions, and the importance of proper maintenance. It covers various types of cone crusher parts, common issues and solutions, and future developments in the industry. Whether you are in the market for a new cone

More

ANALYSIS OF FAILURE STATISTICS FOR CONE CRUSHER

2016年6月10日 The throw of cone crushers is larger than that of primary crushers, to withstand heavier working stresses. The bowl can be held down either by an annular arrangement of springs or by a hydraulic mechanism. Figure 1 presents a simplified view of a cone crusher. Figure 1: A Cone Crusher FMEA, RPN AND TTT-PLOT

More

(PDF) Crushing and Screening Handbook

Crushing and Screening Handbook. Kevin Berrocal. We have the expertise to build a fl eet of track mounted crushing and screening plants for primary, secondary and tertiary stages according to your application. Moving

More

Cone Crusher Parts - 911 Metallurgist

2017年2月19日 Cone Crusher SPIDER CAP. The cast steel spider cap has been designed to serve as a feed distribution plate for coarse materials. It is recessed on the 22, 30, 36 and 48-in. crushers. ... The function is to

More

Maintenance of Cone Crusher Hydraulic System

2022年5月30日 Cone crusher is widely used in mine production due to its high crushing efficiency, low maintenance cost and large output capacity. Cone crushers are divided into spring cone crushers and hydraulic cone crushers, both of which can be used for the production of medium and fine crushing of high-hardness materials.. In the following part,

More

Gyratory Crusher Functional Diagram Crusher Mills, Cone

functional diagram of a cone crusher – Mineral Processing Plant. gyratory crusher,function; function of pedestal grinder; Random Posts: career supervisor mining coal; Crushers – Scribd Manufacturers publish tables of capacity for their crushers of various size as a function of the diagram of a crusher gyratory crushers are used

More