What Type of Crusher Is Best for Primary Crushing? - McLanahan

It is the first stage in the crushing process that can sometimes include

More

Types of Crushers: What You Need to Know - Machinery Partner

One of the most versatile crushers available, hammer mills and impactors can be

More

What Type of Crusher Is Best for Primary Crushing? - McLanahan

It is the first stage in the crushing process that can sometimes include secondary, tertiary and even quaternary crushing stages, depending on the material and the end product requirements. Types of Primary Crushers. There are several types of primary crushers, including: Gyratory Crushers Jaw Crushers Hammermills

More

Crushing Screening - Parker Plant

Designed to operate as fully hydraulic controlled secondary and tertiary machines across a wide range of duties, the Parker cone crusher is a universal machine that can be configured with many alternative cavities and profiles to compliment the requirements of feed and final product required.

More

AMIT 135: Lesson 5 Crushing – Mining Mill Operator

Primary Crushing The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of reduction through a primary crusher

More

Types of Crushers: What You Need to Know - Machinery Partner

One of the most versatile crushers available, hammer mills and impactors can be primary, secondary, and tertiary crushers. Hammer mill crushers use continuous hammer blows to shatter and disintegrate material. They are typically horizontal rotating in an enclosed cylinder casing.

More

Secondary Tertiary Crushing Circuits - 911

Almost all secondary and tertiary crushing circuits use the same type of crusher, the cone crusher. Within a secondary and tertiary crushing circuit there are three main types of machinery,

More

Tertiary crusher, Tertiary crushing and screening plant - All ...

secondary crusher Nordberg® GP series cone stationary high-capacity Capacity: 250, 105 t/h Motor power: 75 kW - 400 kW Weight: 7,350 kg - 28,700 kg ... Series™ cone crushers have been developed to crush feed materials into desired end products efficiently, reliably, and economically.

More

Crushing in Mineral Processing - Eastman Rock

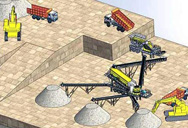

The picture above shows an example of how the crushing plant can be divided into primary, secondary, and tertiary stages. The aggregate produced in a primary crusher is classified using a screen

More

What Is Primary, Secondary, and Tertiary Crushing?

Secondary crushing, as you can imagine, is the second stage of material processing following its initial reduction. At this stage, material will flow through perhaps a second impactor crusher or even a cone crusher, which is

More

8 Tips for Crusher Safety Stewart-Amos Equipment Company

Types of primary crushers include jaw, cone, gyratory and impact crushers. Secondary crushers: Secondary crushers reduce the size of the material before the tertiary stage. Different feeding techniques might be necessary depending on how fine you want the material. Cone crushers are often used in this stage with

More

Crusher Primary Secondary Crusher Mills, Cone Crusher, Jaw Crushers

Crusher For Primary Secondary And Tetiary Process Crusher Crusher For Primary Secondary And Tetiary 27 Views. The liming is the professional mining equipments manufacturer in the world, located in China,India, along with

More

Crusher - an overview ScienceDirect Topics

Primary jaw crushers typically operate in open circuit under dry conditions. Depending on the size reduction required, the primary jaw crushers are followed by secondary and tertiary crushing. The last crusher in the line of operation operates in closed circuit.

More

Screening Equipment - MEKA

Portable Impact Crushers are wheel-mounted rock machines, engineered for primary, secondary and tertiary applications. More Information Portable Cone Crushers Portable are wheel-mounted rock machines, engineered for secondary and tertiary and screening applications. More Information Portable Screens

More

Secondary Crushing Equipment - 911 Metallurgist

The term “ secondary crushing ” has become well established and familiar through long usage; it applies to the crushing stage, either single or multiple, which follows immediately after the primary crusher, taking all or a portion of the product of the primary crushing stage as its feed.

More

Roll Crushers McLanahan

Roll Crushers are designed to handle the primary, secondary and tertiary stage crushing of friable materials such as coal, salt, clay, bauxite, limestone and other minerals of similar characteristics in the mining, power generation and numerous other industries. Applications Coal Crushing Mining Jump to: How Roll Crushers Work Resources

More

What Type of Crusher Is Best for Primary Crushing? - McLanahan

It is the first stage in the crushing process that can sometimes include secondary, tertiary and even quaternary crushing stages, depending on the material and the end product requirements. Types of Primary Crushers. There are several types of primary crushers, including: Gyratory Crushers Jaw Crushers Hammermills

More

Choosing the right crusher - Buying Guides DirectIndustry

impact crusher. Impact crushers can be used as primary crushers, secondary crushers or tertiary crushers depending on the size and technology. They are equipped with beaters, also called hammers, and impact plates. They operate in the following way: they are fed from the upper part, then the stones are hit by the hammers and projected

More

Rock Crushing Equipment Rock Crushers Kemper

In many cases, primary, secondary, and tertiary, and quaternary stations are installed to reduce the rock to the desired size, shape, and consistency. Of course, not all projects require all the stations or stages. Sometimes,

More

Crusher, Crushing plant - All industrial manufacturers

Evortle Mobile Crusher and Recycling Plants (3) F Fabo Crushing Screening Concrete Plants (74) FAM (5) Fast Verdini Srl (1) Fives (2) FLSmidth Dorr-Oliver Eimco (5) FLSmidth MAAG Gear AG (1) FORREC (1) Franklin Miller, Inc. (4) Frewitt Fabrique de machines SA (8) Fritsch GmbH - Milling and Sizing (2) G Gebr. Steimel (1) GENERAL MAKINA (26)

More

Secondary crusher, Secondary crushing and screening plant - All ...

cone crusher. stationary high-capacity secondary. Capacity: 50 t/h - 1,200 t/h. Motor power: 220 kW - 1,800 kW. Complete stationary crushing and screening plant including primary, secondary and tertiary crushing with jaw, cone, hydraulic and VSI crushers in addition to auxiliary items as pre- crusher, ...

More

Crushing in Mineral Processing - Eastman Rock

What is the crushing stage? The picture above shows an example of how the crushing plant can be divided into primary, secondary, and tertiary stages. The aggregate produced in a primary crusher is

More

Crusher equipment models and their applications

The modern crusher range is ideal for shaping applications including making chips, sand, concrete manufacture, and glass recycling. The range includes both horizontal and vertical impact crushers. They are used as primary, secondary, or tertiary crushers depending on the Producer’s final-product-size needs.

More

8 Tips for Crusher Safety Stewart-Amos Equipment Company

Types of primary crushers include jaw, cone, gyratory and impact crushers. Secondary crushers: Secondary crushers reduce the size of the material before the tertiary stage. Different feeding techniques might be necessary depending on how fine you want the material. Cone crushers are often used in this stage with

More

Primary And Secondary Crushing - Crusher Mills

Jaw crusher,Jaw crushers,Primary crushers,Jaw breakers,Mobile . The Jaw crusher is used for Primary crushers and Secondary crushers for crushing all kinds of minerals and rocks with compressive strength less than 320 mpa. There .

More

Crusher Primary Secondary Crusher Mills, Cone Crusher, Jaw Crushers

Crusher For Primary Secondary And Tetiary Process Crusher Crusher For Primary Secondary And Tetiary 27 Views. The liming is the professional mining equipments manufacturer in the world, located in China,India, along with

More

What is a tertiary crusher? - LinkedIn

A tertiary crusher is a type of crusher used to process material that has already been through primary and secondary crushers. Tertiary crushers are typically used in the aggregate industry for ...

More

Types of Rock Crushers Quarry Crushing Equipment Kemper

In many cases, primary, secondary, and tertiary, and quaternary stations are installed to reduce the rock to the desired size, shape, and consistency. Of course, not all projects require all the stations or stages. Sometimes, primary crushing alone may offer enough reduction for your needs.

More

Perfecting the Performance of Secondary Crushers E MJ

Ideally, the deck on the scalping screen should have a cut point equal to the closed side setting (CSS) of the crusher. The feed size to a secondary crusher is typically in the range of 50 mm to 250 mm (up to 300 mm). If the capacity is higher, the acceptable feed size gets larger. After crushing, the product is in the range of 0-60 mm (75 mm ...

More

Cone Crusher - an overview ScienceDirect Topics

5.2.2. Secondary and tertiary cone crushers. Cone crushers were originally designed and developed by Symons around 1920 and therefore are often described as Symons cone crushers. As the mechanisms of crushing in these crushers are similar to gyratory crushers their designs are similar, but in this case the spindle is supported at the bottom

More