Apron Feeders McLanahan

McLanahan Apron Feeders are available in six chain sizes, 16 standard flight widths and an infinite range of lengths — all designed to meet a customer's application requirement. McLanahan Apron Feeders use sealed-for-life undercarriage components with

More

Feeding the facts: Proper sizing and selection of your apron feeder

Basic criteria that should go into properly sizing an apron feeder should include feed rate (peak and normal), material characteristics (such as moisture, gradation

More

Everything You Need to Know about Apron Feeders McLanahan

Apron Feeders consist of cast manganese pans bolted to a dozer-style chain that wraps around a head shaft and tail idler. The chain and pan assembly rides on

More

Design of apron feeders (Journal Article) ETDEWEB - OSTI.GOV

@misc{etde_5465929, title = {Design of apron feeders} author = {Ramos, C M} abstractNote = {This paper discusses practical aspects of apron feeder design,

More

Apron feeder power calculations.pdf - VSIP.INFO

APRON FEEDER POWER CALCULATIONS Basic Parameter: Profile: Length‐hor LIFT Max slope of Apron Feeder profile Capacity‐Working Design capacity Factor Capacity‐

More

Apron Feeder Design Calculation Troubleshooting - IEM

Physical Characteristics: Angle of Repose: degrees Moisture Content Minimum % Maximum % Lump Size: Max (P100) Average (P80) Material Temperature: Deg C Deg F FEEDER

More

An expert insight into apron feeder evolution - Quarry

“Cast and forged apron feeder chains are an example of this. Traditional chain designs that required regular lubrication have given way to sealed and lubricated (SALT) units, which do not require any

More

CONCEPTS OF FEEDER DESIGN AND PERFORMANCE IN

The basic design features of belt and apron feeders is presented. The need for feeders and mass-flow hoppers to be designed as an integral unit to promote uniform feed is

More

FAILURE ANALYSIS AND DESIGN OF DRIVE SHAFT IN HEAVY

IN HEAVY DUTY APRON FEEDER IN POWER PLANT Anil Pathak1, Ankur Singh2, Dr. Manish Bhargava3 1Maharishi Arvind Institute of Engineering and Technology, ... FEA

More

Apron Feeders McLanahan

McLanahan Apron Feeders are available in six chain sizes, 16 standard flight widths and an infinite range of lengths — all designed to meet a customer's application requirement. McLanahan Apron Feeders use sealed-for-life undercarriage components with oversized head shaft bearings to reduce monitoring and keep maintenance requirements to a ...

More

Apron Feeders - AUMUND Group

Apron Feeders type BPB, BPB-S, and BPB-SF Flexible solution for Crusher Feeding, Wagon Unloading, Hopper Discharge or Stockpile Discharge AUMUND Apron Feeders type BPB, BPB-S and BPB-SF offer a wide

More

Apron feeder -

Apron feeders 1 Apron feeder Robust design, improved uptime. 2 Apron feeders Apron feeders 3 Material handling solutions from With more mines and processing plants running round the clock, operators are opting for equipment that is more reliable and requires less maintenance. ’s vast assortment of material

More

Feeding the facts: Proper sizing and selection of your apron feeder

As stated above in the first segment, bulk density of the ore/rock is one of the basic criteria requirements that should be included for proper apron feeder sizing. Density is the weight of material in a given volume, and usually bulk density is measured as tons/cubic meter (t/m³) or pounds/cubic foot (lbs/ft³).

More

Industrial Solutions Apron feeders - ThyssenKrupp

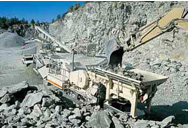

Apron feeder RKF 2.2 x 15.8 - D8 with inboard chain Apron feeder RKF 3.4 x 17.0 - D9 with outboard chain Apron feeders are designed for conveying capacities of more than 14,000 t/h and can be integrated into stationary, semi-mobile or mobile plants. Stationary single-shaft impact crusher (right) fed by two apron feeders

More

Apron feeders: the material handling workhorses

Apron feeders are designed to be ran at variable speeds to extract from storage and feed downstream at a controlled rate of speed for maximum efficiency. The material could vary depending on factors

More

Apron feeder power calculations.pdf - VSIP.INFO

APRON FEEDER POWER CALCULATIONS Basic Parameter: Profile: Length‐hor LIFT Max slope of Apron Feeder profile Capacity‐Working Design capacity Factor Capacity‐ design Material: Lump size ‐ Normal Lump size max Moisture content Fines content Bulk Density ‐ vol. Bulk Density ‐ Load Angle of repose Volumetric Capacity reqd CHAIN

More

(PDF) Design of Belt and Apron Feeders An Overview

An overview of feeder design and performance focussing on belt and apron feeders is presented The importance of correct hopper and feeder interfacing is stressed The objective is to achieve uniform draw-down in

More

Hopper Discharge Systems - Aumund

The apron feeder with arched plates is the perfect equipment for conveying sticky raw materials such as gypsum, anhydride, clay or a marl-clay mix. The arched plates of the feeder form a surface perfectly matching the drive and tail sprockets, hence allowing cleaning of the plates with a scraper. Fitted with a weighing rail and a

More

Expert advice on the evolution of apron feeder design

An example of this can be seen in the design of apron feeder pans, also known as flights. Pans are high impact, abrasion resistant wear parts responsible for extracting material and discharging it from the feeder. ... Sometimes producers will opt for a cheaper machine that is satisfactory for operating parameters, but doesn’t have the ...

More

FAILURE ANALYSIS AND DESIGN OF DRIVE SHAFT IN HEAVY

Design modification and optimization of drive shaft for apron feeder can be followed for other heavy equipment. Many researchers have been investigated about hybrid drive to the yokes of universal joints but this project provides the analysis of the shaft design in many aspects. II SPECIFICATIONS OF DRIVE SHAFT

More

An expert insight into apron feeder evolution - Quarry

“Cast and forged apron feeder chains are an example of this. Traditional chain designs that required regular lubrication have given way to sealed and lubricated (SALT) units, which do not require any lubrication throughout the life of the unit.

More

Proper sizing and selection of your apron feeder - MINING.COM

Apron feeder sizing requires basic knowledge of plant data to be able to accurately fill in the criteria needed for a vendor’s “application data sheet” (or however the vendor receives their ...

More

AF Apron Feeder - FLSmidth

Design features Robust construction The feeder is built into a sturdy frame with rails. The rails carry the chains that have grease-lubricated rollers. The aprons are designed to deflect a little when hit by big rocks. The impact is absorbed by the aprons themselves and by impact rollers placed below the aprons. The impact rollers, which are

More

Apron Feeders McLanahan

The Apron Feeder consists of a frame, undercarriage components, head shaft, tail shaft, flights and a drive. The undercarriage chain wraps around the head shaft and tail idler, and flights are bolted to the strands of chain. The chain and flight combination rides on undercarriage rollers.

More

Apron feeder -

Apron feeders 1 Apron feeder Robust design, improved uptime. 2 Apron feeders Apron feeders 3 Material handling solutions from With more mines and processing plants running round the clock, operators are opting for equipment that is more reliable and requires less maintenance. ’s vast assortment of material

More

Feeding the facts: Proper sizing and selection of your apron feeder

As stated above in the first segment, bulk density of the ore/rock is one of the basic criteria requirements that should be included for proper apron feeder sizing. Density is the weight of material in a given volume, and usually bulk density is measured as tons/cubic meter (t/m³) or pounds/cubic foot (lbs/ft³).

More

AF Apron Feeder - FLSmidth

Design features Robust construction The feeder is built into a sturdy frame with rails. The rails carry the chains that have grease-lubricated rollers. The aprons are designed to deflect a little when hit by big rocks. The impact is absorbed by the aprons themselves and by impact rollers placed below the aprons. The impact rollers, which are

More

Industrial Solutions Apron feeders - ThyssenKrupp

Apron feeder RKF 2.2 x 15.8 - D8 with inboard chain Apron feeder RKF 3.4 x 17.0 - D9 with outboard chain Apron feeders are designed for conveying capacities of more than 14,000 t/h and can be integrated into stationary, semi-mobile or mobile plants. Stationary single-shaft impact crusher (right) fed by two apron feeders

More

Hopper Discharge Systems - Aumund

The apron feeder with arched plates is the perfect equipment for conveying sticky raw materials such as gypsum, anhydride, clay or a marl-clay mix. The arched plates of the feeder form a surface perfectly matching the drive and tail sprockets, hence allowing cleaning of the plates with a scraper. Fitted with a weighing rail and a

More

Conveying Equipment Apron Feeders - dokaendustri.tr

DesignParameters Designed up to 1,653 STPH (1,500 MTPH) larger capacities upon request. Capable of handling a wide range of abrasive and lumpy materials Maximum Incline (25 degrees from the horizontal) Capable of handling material up to 600° F (315° C) C-C Designed up to 50 Ft (15.24 m)larger C-C upon request Materials Handled Limestone Sand

More

Types of Feeders and Their Applications McLanahan

This type of feeder is higher on capital investment but is also high on investment returns. Apron Feeders are a favorite in the mining industry because they can operate 24/7 and go years between maintenance periods. Apron Feeder feeding a Triple Roll Crusher. Apron Feeder Fast Facts. Used for small and large capacities

More

Expert advice on the evolution of apron feeder design

An example of this can be seen in the design of apron feeder pans, also known as flights. Pans are high impact, abrasion resistant wear parts responsible for extracting material and discharging it from the feeder. ... Sometimes producers will opt for a cheaper machine that is satisfactory for operating parameters, but doesn’t have the ...

More

FAILURE ANALYSIS AND DESIGN OF DRIVE SHAFT IN HEAVY

Design modification and optimization of drive shaft for apron feeder can be followed for other heavy equipment. Many researchers have been investigated about hybrid drive to the yokes of universal joints but this project provides the analysis of the shaft design in many aspects. II SPECIFICATIONS OF DRIVE SHAFT

More

Proper sizing and selection of your apron feeder - MINING.COM

Apron feeder sizing requires basic knowledge of plant data to be able to accurately fill in the criteria needed for a vendor’s “application data sheet” (or however the vendor receives their ...

More

MMD Group of Companies - Feeders

MMD Apron feeders provide reliable feeding to the sizer plant. Allowing direct material loading onto the apron plates ... The MMD Feeder's unique design allows dumping of run-of-mine material even when the feeder is running empty. The ability to load at anytime delivers continuity and flexibility of operation for maximum production and efficiency.

More

apron feeders operating parameters and the control thereof

apron feeders operating parameters and the control thereof about apron feeders operating parameters and the control thereof. design parameters, ... track crusher Vibrating Feeder Manual; ... AME Ltda’s personnel use their plant operation expertise in the development of plant layouts. ... and Control Bench and Pilot ...

More

Chain Conveyors - Practical Calculations - PDHonline

Apron feeders have capacities up to 6000 t/h and are able to transport materials with maximum lump size up to 2000 mm. The large size of material lumps is the cause for the increase of the width of the aprons and the height of the skirts. The presence of fixed skirts causes additional resistances due to skirt friction.

More