Comminution and classification technologies of iron ore

Most of the high-grade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for

More

Iron processing - Ores, Surface Mining, Sintering, and Pelletizing

Crushing and screening are straightforward mechanical operations that do not alter an ore’s composition, but some ores need to be upgraded before smelting. Concentration

More

11.23 Taconite Ore Processing - U.S. Environmental Protection

Processing of taconite consists of crushing and grinding the ore to liberate iron-bearing particles, concentrating the ore by separating the particles from the waste material

More

(PDF) Overview of Mineral Processing Methods

It is a process of ore preparation, milling, and ore dressing or ore beneficiation. Ore dressing is a process of mechanically

More

Ore Processing Multotec

The primary processes are crushing and grinding of ore, ore sizing and separation. To separate the ore into applicable sizes for further processing, screening, classifying,

More

Life cycle assessment of iron ore mining and processing

An LCA study of iron ore and bauxite mine sites concluded that loading and haulage operations were responsible for the highest greenhouse gas (GHG)

More

Overview of Ore Washing in the Mineral Processing Industry

Ore washing consists of two operations: fragmentation and separation. The crushing operation is mainly to use the washing and soaking effects of water to

More

Iron ore crushing and screening process - sbmmill

Iron ore screening equipment generally uses a circular vibrating screen to screen the materials after the second crushing. Generally, materials with a size of

More

National Emission Standards for Hazardous Air Pollutants:

Taconite iron ore processing plants separate and concentrate iron ore from taconite, a low-grade iron ore containing 20- to 25-percent iron, and produce taconite

More

Comminution and classification technologies of iron ore

Most of the high-grade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct shipping ore (DSO). This involves multistages of crushing and screening to obtain lump (−31.5 + 6.3 mm) and fines (approximately −6.3 mm) products.

More

11.23 Taconite Ore Processing - U.S. Environmental Protection

Processing of taconite consists of crushing and grinding the ore to liberate iron-bearing particles, concentrating the ore by separating the particles from the waste material (gangue), and pelletizing the iron ore concentrate. A simplified flow diagram of these processing steps is shown in Figure 11.23-1.

More

(PDF) Overview of Mineral Processing Methods

It is a process of ore preparation, milling, and ore dressing or ore beneficiation. Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue...

More

Life cycle assessment of iron ore mining and processing

An LCA study of iron ore and bauxite mine sites concluded that loading and haulage operations were responsible for the highest greenhouse gas (GHG) emissions, while crushing and grinding ...

More

Pre-selecting and tailings discarding process of lean magnetite

Abstract: The invention discloses an iron improvement and silicon reduction beneficiation method of high ferrosilite and lean magnet iron ore, the method comprises the following processes of crushing-screening,fine crushing, dry-type preconcentration tailings discardinghigh-pressure roller milling, coarse particle magnetic separation, and

More

COMMON IRON ORE CRUSHING AND SCREENING PROCESS

Some crushing and screening processes commonly used in concentrators are now introduced. 1. Two-stage Crushing Process. The two-stage crushing process has two forms: two-stage open circuit and two ...

More

National Emission Standards for Hazardous Air Pollutants: Taconite Iron

Taconite iron ore processing plants separate and concentrate iron ore from taconite, a low-grade iron ore containing 20- to 25-percent iron, and produce taconite pellets, which are 60- to 65-percent iron. Taconite iron ore processing includes crushing and handling of the crude ore, indurating, and finished pellet handling.

More

Iron ore crushing and screening process - sbmmill

Iron ore screening equipment generally uses a circular vibrating screen to screen the materials after the second crushing. Generally, materials with a size of 10mm or less can be screened for dry selection. After screening, materials with a size of 10-40mm enter the fine crusher for fine crushing.

More

CESTAT, Iron Ore, Benefit Of Exemption - LiveLaw

CESTAT Mumbai holds that process of crushing and screening 'Iron Ore' after mining and its subsequent blending with 5-10% iron ore concentrate would result in the classification of goods imported ...

More

Magnesite Ore Processing: Separation and Calcination

The processing flow is as follows: 1 Crushing: Use a jaw crusher, roll crusher, and vibrating screen to form a two-stage-closed circuit crushing system to crush the raw magnesite ore to 1mm. 2 Calcination: Send the raw ore into a rotary kiln for calcination at a temperature of 700-800°C for 1 hour. 3 Crushing:

More

Iron ore fines - BIMCO

Description: Iron ore fines come from the natural raw iron ore through the process of mining, crushing and screening, where the iron ore is separated into lumps and fines. Iron ore is done in this fashion so that it can be used for the iron/steel making industry. When the iron content in the processed iron ore contains more than 60%, which ...

More

EPA proposing mercury rule for taconite iron ore processing

The Taconite Iron Ore Processing NESHAP applies to each new or existing ore crushing and handling operation, ore dryer, pellet indurating furnace, and finished pellet handling operation at a taconite iron ore processing plant that is (or is part of) a major source of HAP emissions. There are currently eight taconite iron ore processing

More

Hard Rock Lithium Processing - SGS

Metallurgical results show that a high grade lithium concentrate (>7%) can be achieved. GRINDABILITY TESTS SGS supports the minerals and chemical industries in the design and operation of efficient crushing and grinding

More

Beneficiation of Iron Ores – IspatGuru

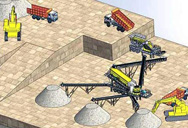

The crushing, grinding and screening systems of an IOB plant are to be designed taking into account the requirements of the downstream beneficiation processes. The crushing units may include primary, secondary, tertiary and quaternary crushing systems. Jaw, gyratory, cone, and roll crushers are used for ore crushing.

More

Comminution and classification technologies of iron ore

This involves multistages of crushing and screening to obtain lump (−31.5 + 6.3 mm) and fines (approximately −6.3 mm) products. Low-grade hematite ores, on the other hand, need to be upgraded to achieve the required iron content which involves more complicated ore beneficiation processes.

More

11.23 Taconite Ore Processing - U.S. Environmental Protection

Processing of taconite consists of crushing and grinding the ore to liberate iron-bearing particles, concentrating the ore by separating the particles from the waste material (gangue), and pelletizing the iron ore concentrate. A simplified flow diagram of these processing steps is shown in Figure 11.23-1.

More

Pre-selecting and tailings discarding process of lean magnetite

Abstract: The invention discloses an iron improvement and silicon reduction beneficiation method of high ferrosilite and lean magnet iron ore, the method comprises the following processes of crushing-screening,fine crushing, dry-type preconcentration tailings discardinghigh-pressure roller milling, coarse particle magnetic separation, and

More

Life cycle assessment of iron ore mining and processing

An LCA study of iron ore and bauxite mine sites concluded that loading and haulage operations were responsible for the highest greenhouse gas (GHG) emissions, while crushing and grinding...

More

COMMON IRON ORE CRUSHING AND SCREENING PROCESS

Some crushing and screening processes commonly used in concentrators are now introduced. 1. Two-stage Crushing Process. The two-stage crushing process has two forms: two-stage open circuit and two ...

More

National Emission Standards for Hazardous Air Pollutants: Taconite Iron

Taconite iron ore processing plants separate and concentrate iron ore from taconite, a low-grade iron ore containing 20- to 25-percent iron, and produce taconite pellets, which are 60- to 65-percent iron. Taconite iron ore processing includes crushing and handling of the crude ore, indurating, and finished pellet handling.

More

Hard Rock Lithium Processing - SGS

Metallurgical results show that a high grade lithium concentrate (>7%) can be achieved. GRINDABILITY TESTS SGS supports the minerals and chemical industries in the design and operation of efficient crushing and grinding

More

EPA proposing mercury rule for taconite iron ore processing

The Taconite Iron Ore Processing NESHAP applies to each new or existing ore crushing and handling operation, ore dryer, pellet indurating furnace, and finished pellet handling operation at a taconite iron ore processing plant that is (or is part of) a major source of HAP emissions. There are currently eight taconite iron ore processing

More

CESTAT, Iron Ore, Benefit Of Exemption - LiveLaw

CESTAT Mumbai holds that process of crushing and screening 'Iron Ore' after mining and its subsequent blending with 5-10% iron ore concentrate would result in the classification of goods imported ...

More

Magnesite Ore Processing: Separation and Calcination

The processing flow is as follows: 1 Crushing: Use a jaw crusher, roll crusher, and vibrating screen to form a two-stage-closed circuit crushing system to crush the raw magnesite ore to 1mm. 2 Calcination: Send the raw ore into a rotary kiln for calcination at a temperature of 700-800°C for 1 hour. 3 Crushing:

More

Iron ore concentration plants Mining Quarry Plant

Iron ore concentration plant,Iron ore screening equipment Mineral iron ore concentration plant process, which includes milling (crushing and grinding); washing; filtration; sorting; sizing; gravity concentration; magnetic mobile iron ore concentration plant Iron Ore Concentrate Plant in Zimbabwe ? Stone

More

Crushing, Grinding and Concentration of the Ore - Class Notes

1) Crushing and grinding of the ore 2) Concentration or benefaction of the ore 3) Extraction of crude metal from concentrated ore 4) Purification or refining of the metal (1) Crushing and Grinding of the Ore. The ores occur in nature as huge lumps. They are broken to small pieces with the help of crushers or grinders.

More

Eco-efficient and cost-effective process design for magnetite iron ore ...

Iron ore has a special place in the global mining industry, judging by the volumes of ore processed and the energy usage. ... The magnetite concentrate weight recovery, SG, Ai, iron and silica content were based on the relationships presented on Formula 1. ... Primary crushing – secondary crushing – screening – Open HPGR –

More

Iron ore :: ArcelorMittal Liberia

ArcelorMittal Liberia’s iron ore is a direct shipped iron ore (DSO) product. DSO means that apart from some primary crushing, screening and blending at the mine, the iron ore is mined, shipped and consumed in about the same form as it is extracted from the ground. DSO is a sintering fines material. It is sold to

More